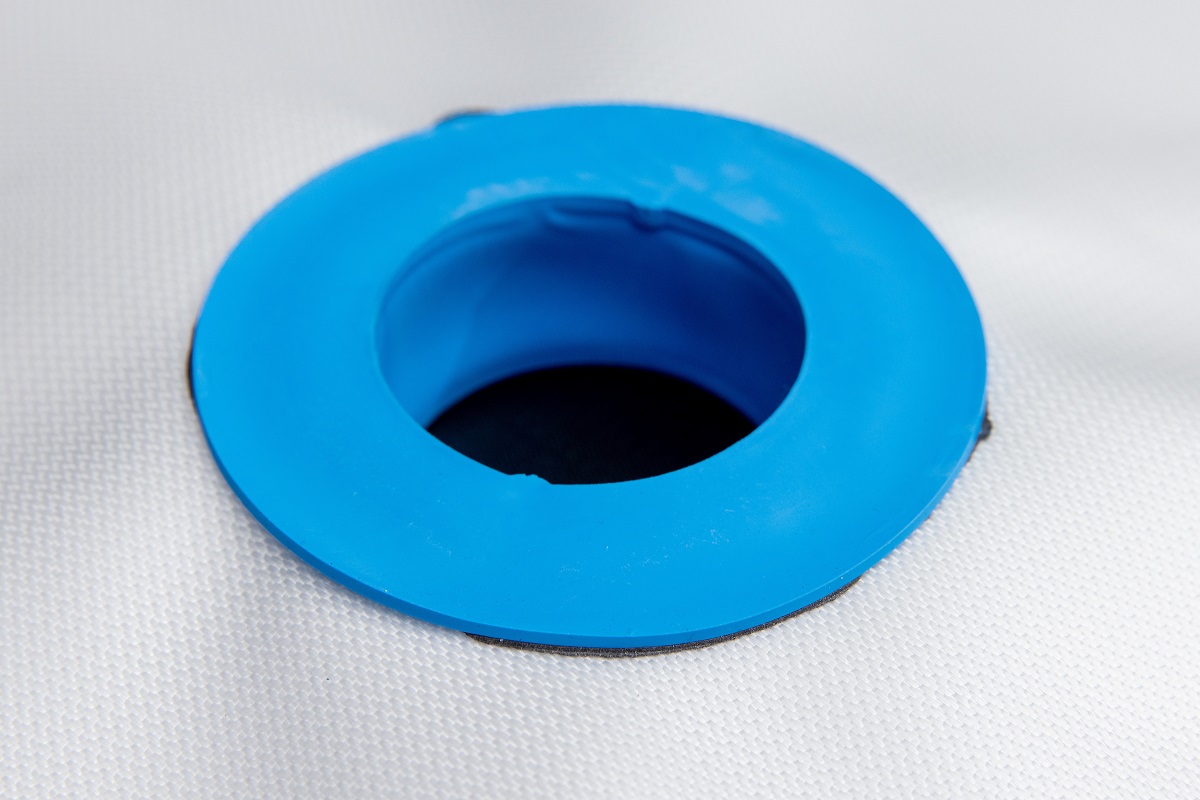

Welded HPR Feed Necks

Micronics’ welded feed necks cannot leak or bypass product through stitch holes, ensuring that there will be no sudden failures and yield losses when you are filtering expensive products.

Micronics’ HPR feed neck is fully resistant to high velocity, abrasive slurries, and all chemical conditions.

In addition to the HPR design, there are other high-performance filter cloth neck types such as the SK neck design, heat-treated coated neck design, and clip neck design. Other special vinyl-coated and FDA coated neck designs are available when required.

Read more about Micronics’ Welded HPR Feed Neck Design here and see how this design can significantly improve your press performance!

SK Feed Necks

This new patented product allows rigid, plastic necks to be attached to polypropylene cloths. The performance benefits are the same as with the HPR design with the additional advantage of high abrasion resistance for difficult slurries. Micronics’ abrasion-resistant design leads to longer filter cloth life for better operating economics.

Heat-Treated Coated Feed Necks

For applications where cloth attachments are desired, a heat-treated coated neck should be selected. This neck type uses synthetic rubber formulations, and is determined by Micronics to be chemically-stable and abrasion-resistant. They will always outperform hand-applied treatments.

Clip Necks

This is a patented, Micronics-designed neck used in conjunction with special plate modifications, allowing the use of single filter cloths. This innovative design reduces cloth changeout times, lowers overall cloth costs, and improves filter press operations.