As we come to the end of 2020, we wanted to take a moment to reflect on filtration issues, innovations, and the impact of COVID-19.

The perspective shared here is based on a recent conversation with Micronics’ President and CEO, Chris Cummins.

Home > Leadership Perspectives – Chris Cummins, CEO, December 2020

As we come to the end of 2020, we wanted to take a moment to reflect on filtration issues, innovations, and the impact of COVID-19.

The perspective shared here is based on a recent conversation with Micronics’ President and CEO, Chris Cummins.

How have you seen COVID-19 affecting the filtration industry? What responses has Micronics implemented to best serve clients and protect the employee base during this challenging time?

We have certainly felt the effects of COVID-19 in terms of our customers and their operations, our suppliers, and our employee base. We are very optimistic about the wide-scale implementation of the COVID-19 vaccines in 2021, but what has been important over these past 10 months is how the Micronics team has, day in and day out, responded to and stepped up during this period of challenge. While the coronavirus pandemic has certainly had an impact on Micronics and the entire filtration industry, it has also given us the opportunity to think, act, and innovate in new ways.

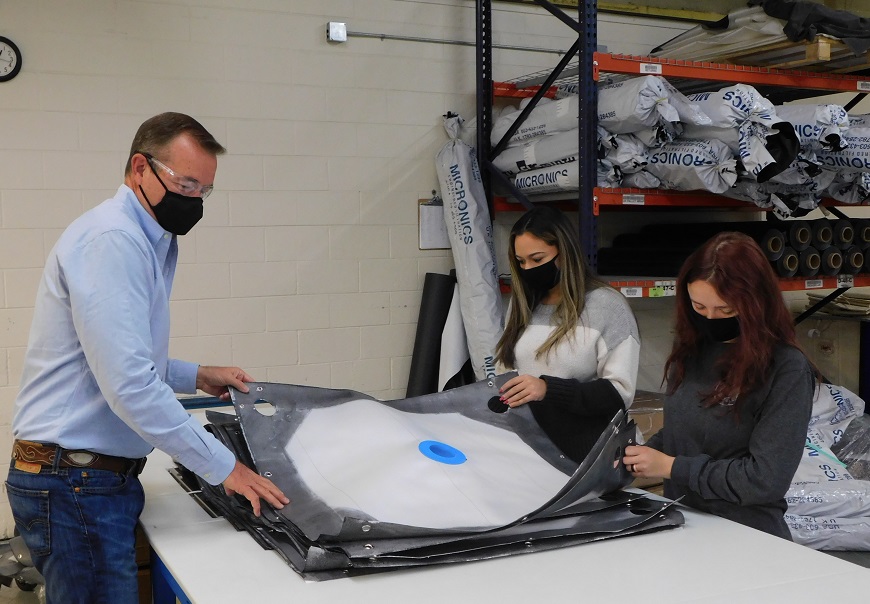

First, we have taken many precautions to keep our employees safe while focusing on servicing our customers’ needs and keeping response-time and lead-times short. Lead by a great operations team, we have added weekend shifts in our filter media and filter press operations, and we have extended second shift to get orders out on time. Micronics has two filter media plants in North America and this flexibility has been critical to servicing our wet and dry filtration filter media needs. We have put strong safety protocols in place for our office, sales, service, and manufacturing teams to ensure we have the best possible practices both internally and with visits in the field to our customers. More than just spacing – we have implemented additional deep cleaning of our offices and plants, daily temperature checks, staggered break times, and wide availability of masks and sanitizers for our employees, as recommended by the CDC.

We continue to lead with an ongoing daily focus on operational excellence, a bias for action, and empathy. It is not an “or” but an “and.” Some of our employees have needed to take time off to care for loved ones. Many team members have needed flexibility while waiting for COVID-19 test results in order to safely come back to work. We are particularly grateful for our employees’ dedication and resilience during this challenging time. Our products exist because of our people.

We continue to lead with an ongoing daily focus on operational excellence, a bias for action, and empathy. It is not an “or” but an “and.” Some of our employees have needed to take time off to care for loved ones. Many team members have needed flexibility while waiting for COVID-19 test results in order to safely come back to work. We are particularly grateful for our employees’ dedication and resilience during this challenging time. Our products exist because of our people.

What are some ways in which Micronics has innovated in new and important ways during the past year?

Remote Solutions:

For Micronics, challenges create opportunities. During 2020, we have been successful in performing remote commissioning of multiple filter presses for clients in the mining and mineral processing industries in the Americas. Despite the situation, we met the customers’ expectations, all while providing remote solutions. We are continuing to provide a range of service solutions both in the field and remotely, depending on the customers’ needs. We look forward to further expanding our range of service solutions in 2021.

Industry-leading Innovations for Mining & Mineral Processing:

Industry-leading Innovations for Mining & Mineral Processing:

Amid the COVID pandemic, we have nonetheless been able to launch an industry-leading innovation in filter media with the introduction of MINE-XLL™ to the mining and mineral processing industry! MINE-XLL™ has been trialed at numerous mines and we are getting very strong performance reviews from the field. Our customers are pleased and impressed with the extra-long lifetime (XLL) of the MINE-XLL™. Being able to extend the time between changeouts by 3-fold has delivered a lot of value to our customers. We are also happy to report that MINE-XLL™ is gaining traction throughout the Americas, the EU, Australia, and Asia, both for mineral concentrate and tailings applications.

Innovative Pilot Testing Solutions:

Micronics clients continue to rely upon our bench-scale test press, the MicroPress. During 2020, this innovative 150mm filter press has been used in many on-site trials for novel new applications and existing applications to hone-in on filter media selection, appropriate sizing for full-scale filter press unit, and process optimization. Our Sales Managers are all hands-on and work with client personnel to facilitate successful field trials. Our Engineering, Sales, and Service teams have been able to provide excellent collaboration via on-line conferencing with platforms such as Teams, Zoom, and other such tools.

Total Baghouse Solutions:

On the baghouse solutions side of the house, the Micronics team worked closely with our clients in implementing planned preventative maintenance programs and scheduled plant downtime to lower their costs, make sure that our service crews are properly scheduled, and ensure that the proper inventory of filter bags and spare parts are in place.

For those customers who have experienced upset conditions or unplanned outages and did not have adequate stock levels in their warehouse, Micronics’ filter bag manufacturing plant has continued to provide quick turnaround times and expedited shipments. “Well done” to our manufacturing team, whose support allows our customers to quickly and efficiently bring their baghouses back on-line, minimizing the impact on their facilities.

Over the course of this year, our clients have benefited from the tremendous expertise of our service teams who have continued to perform filter bag changeouts and mechanical repairs in these challenging conditions. In spite of Covid-19, the service team has had a very busy year and we are looking forward to continuing infrastructure improvements impacting cement, steel, mining, and other industries.

From an innovation perspective, our dry filtration team has worked very closely with our baghouse customers to identify opportunities for increasing filter bag life through a thorough understanding of customers’ operating conditions and the filter media upgrades that would address specific operating condition challenges. This year, we brought filtration solutions to the biomass renewable energy and steel manufacturing segments that resulted in improved filtration efficiencies and filter bag life, providing them with a lower total cost of ownership.

We anticipate additional industry-leading innovations for our wet filtration and dry filtration clients in 2021. Stay tuned!

While none of us have a crystal ball, is there an outlook you would like to share relative to 2021? Any key trends or observations? A special message to our customers, employees, and supply partners?

We are feeling solid tailwinds heading into 2021, which is gratifying, as customers are beginning to take projects which were previously on hold due to the coronavirus into the project execution queue. We are continuing to see a strong emphasis on projects and technologies that are creating a cleaner, safer world for communities, industry, and the planet.

Delivering sustainable solutions is always a key emphasis for Micronics and we will continue to provide total engineered filtration solutions, end-to-end from filter media to service. Our customers tell us that they value that our offerings are all under the trusted Micronics banner from baghouse solutions to pressure filtration solutions. In these challenging times, simplifying things for clients has been and continues to be a high priority!

We are seeing our clients in the mining, mineral processing, metals, and automotive industries – to name a few sectors – embracing the recovery, recycle, and reuse of precious resources. Micronics is an integral part of this shift in that our technologies support the growing circular economy.

We, like citizens around the globe, look forward to the expedient distribution of the coronavirus vaccines in 2021 and its significant positive impact on global GDP growth.

We have a strong team and Micronics looks to 2021 and beyond with both optimism and enthusiasm as we continue to work closely with our global customers across diverse industries in providing the industry’s best total engineered filtration solutions. We believe there is significant pent-up demand and we will be ready to support our customers’ growth as their operations return to full capacity over the next few months.

My thanks to all our employees, customers, and supply partners for standing next to us in 2020 as we weathered multiple challenges and got stronger. Looking forward to a great 2021 – Let’s Go!

– Chris Cummins, President and CEO, Micronics Engineered Filtration Group, 12/23/20

About the Micronics Engineered Filtration Group

The Micronics Engineered Filtration Group is a global provider of customized engineered filtration solutions for demanding applications from mining to chemicals to cement to recycling for the growing circular economy and our planet. The Micronics Engineered Filtration Group consists of leading wet and dry brands under the Micronics banner including Southern Filter Media (“SFM”), C.P. Environmental (“CPE”), United Process Control (UPC), and AeroPulse.

Micronics is a worldwide expert in liquid/solid separation. Incorporated in 1983 and founded by Barry Hibble, Micronics has been a portfolio company of Vance Street Capital, a Los Angeles-based private equity firm, since 2013. Beginning in late 2014 and continuing into 2015, Micronics expanded from liquid filtration alone to include a strong and complementary focus on dry filtration, providing industry-leading air pollution control products and services with the acquisitions of SFM, EPE, UPC, and AeroPulse.

Micronics serves customers’ total filtration solutions needs in mining and mineral processing; energy, power generation; industrial; battery recycling; chemical manufacturing; pigments and dyes; food and beverage; steel and iron processing; aggregates, cement, and asphalt; pharmaceutical and biotech; and water/wastewater treatment.

The company’s tagline underscores its breadth and capabilities: Single Source for Filter Press and Air Pollution Control Needs.

Whether for filter press operations for wastewater treatment or for baghouse dust collectors for delivering cleaner air, Micronics’ mission is to consistently deliver the filtration expertise and innovative problem-solving that help optimize and propel customers’ operations. We are committed to our customers’ success. For more information, please visit: www.micronicsinc.com.

About Vance Street Capital

Vance Street Capital LLC is a middle-market private equity firm focused on investing in highly engineered solutions businesses across the industrial technology, medical, and aerospace & defense markets. For over two decades, Vance Street’s partners have worked with management teams and family owners to accelerate revenue growth, improve operations, and acquire strategic assets for the companies in their investment portfolio. For more information, please visit: www.vancestreetcapital.com.

Marketing and Media Contact:

Francine S. Bernitz

Marketing Director, Micronics Engineered Filtration Group

Francine.Bernitz@Micronicsinc.com

781.789.3178

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.