BFM Fittings are a patented industrial connector technology that makes manufacturing cleaner, safer and more efficient. The Micronics Engineered Filtration Group is one of only a few approved distributors of BFM Fittings in the United States. We pride ourselves on our service and quickly returning customers’ calls. Contact Us today to learn how BFM Fittings can help your company!

BFM Fittings – Flexible Connectors

BFM Fittings Advantages

BFM Fittings Advantages

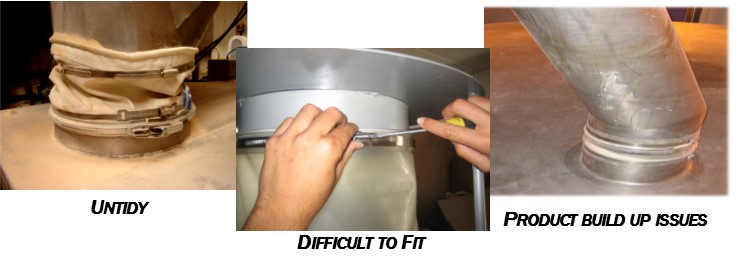

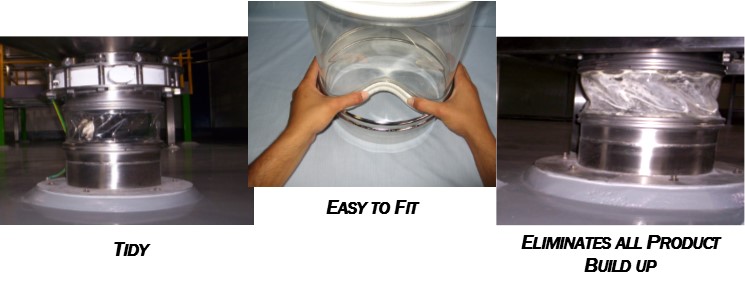

- BFM Fittings ensure an absolute seal meaning there are no leaks or dust. This snap-in, flexible connector, and spigot eliminates the leaking problems associated with traditional hose clamp systems. Additionally, the fittings prevent` product build-up to keep your equipment clean. Whether under positive or negative pressure, BFM Fittings improve system performance.

- Health and safety risks to workers’ hands are reduced when installing BFM Fittings as no tools are required. These fittings further increase safety and productivity by eliminating connector blowouts and leakage as they seal from the inside. Traditional hose-clamp systems frequently have hose clamp failure due to over-pressure and explosions, but pressure only tightens the seal of our BFM fittings.

- BFM Fittings also increase the efficiency of your process. The more flexible, robust materials of BFM connectors extend the product life. The snap-in fit makes installation easy and standardized BFM connector sizes mean you need to keep less stock on hand. Changing connectors can be completed in less than a minute preventing expensive outages of your equipment. BFM Fittings are the perfect fit every time.

- BFM Fittings are specially designed for sifters that rotate, shake and vibrate. Their flexibility ensures that movement does not damage the system. The clear material makes product checks easy as workers can monitor the quality of the product as it goes through the piping without having to stop the process.

| Benefits | Standard House Clamped Flexible Connectors | BFM™ System |

|---|---|---|

| Hygiene | Product building up between the flexible connector and the side wall of the spigot | No crevice for product to get caught in |

| Sizing | From inaccuracies in measuring on-site through to production, it can be very difficult to get a perfect fit of a hose-clamped connector | Perfect fit every time |

| Fitting | Both the speed and accuracy of fitting hose clamps can vary widely and often clamps are not fitted correctly | Can only fit in exactly the correct place, i.e. in or out |

| Explosion | In an over pressure situation hose clamps are normally always the weakest link and give up or let go long before the flexible connector would be due to rupture | Only seals tighter under high pressures |

| Standard Sizes | Current flexible connectors are made in any size whatsoever, hence there are thousands of different sizes | Set standard sizes in 50mm increments helps standardize stock holdings of spare parts |

| Health & Safety | When using screwdrivers to tighten up hoseclips, damage is common to the flexible connector and even the installer’s hands | Tool-free connector changing, simply snap in with your hands |

From This

From This

BFM Fittings Specifics

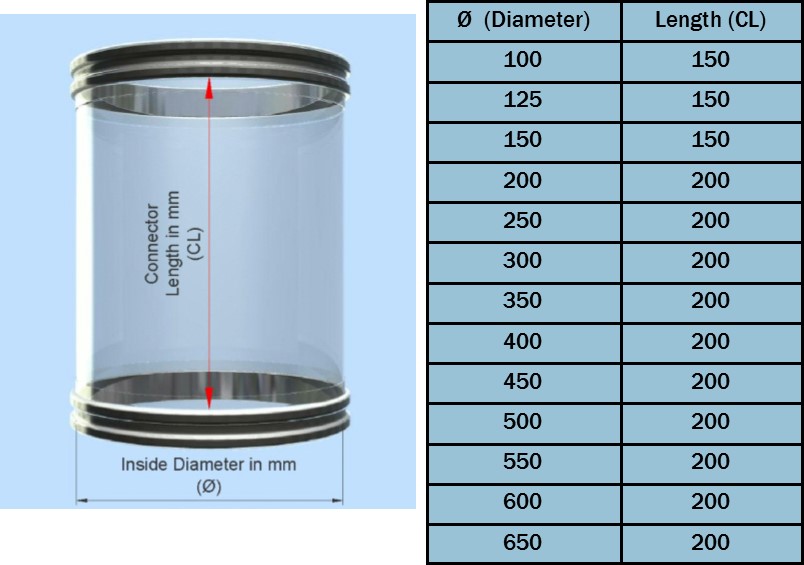

BFM Fittings are available in a variety of diameters in 2-inch increments, from 4 inches up to 65 inches. Connectors are available in lengths starting at 3 inches then in 2-inch increments from 4 inches up to 19 feet, 8 inches. Call us today and we will work with you to determine the perfect standardized size for your application. Your BFM fittings will be made to order and shipped to a Micronics location where we can keep your specific fittings on-site, ready to be sent to you whenever you need them.

BFM Fittings are available in a variety of diameters in 2-inch increments, from 4 inches up to 65 inches. Connectors are available in lengths starting at 3 inches then in 2-inch increments from 4 inches up to 19 feet, 8 inches. Call us today and we will work with you to determine the perfect standardized size for your application. Your BFM fittings will be made to order and shipped to a Micronics location where we can keep your specific fittings on-site, ready to be sent to you whenever you need them.

Material options include:

- Clear polyurethane – USDA Dairy equipment approved

- Breathable polyester – for high-temperature installation

- Breathable polypropylene – for low-temperature installation

- Polytetrafluoroethylene (PTFE) – for very high temperatures, caustic or acid

- Kevlar – flame retardant for over-pressure and potentially explosive applications

- Polypropylene – light blocking for sensitive applications

BFM Fittings Applications

BFM fittings are FDA approved and are a great solution for the food industry. They are also useful in the chemical, mineral, and pharmaceutical industries.

- Food processing

- Chicken processing

- Bakeries

- Powder connections

- Vibrating and oscillating sifters

- Conveyers and feeders

- Fans

- Baghouses

- Silos and bin inlet and outlets

- Cyclones

- Blenders

- Vibro tubes

- Rotary valves

- Pharmaceutical

- Plasma

- Mineral

- Concrete manufacturing

- Plaster manufacturing

- Chemical

- Feed mill

- Plastic

There is no limit to the possible applications for the BFM fittings. If you think BFM fittings may be the solution for your pipe connection, contact us and we’ll work with you to find your best fit.

Take advantage of the Micronics Engineered Filtration Group’s excellent customer service and choose us as your BFM fittings supplier. Our technicians will be there when you need them, ready to help with any issue.

Contact Our Experts

Micronics Is Your Trusted Partner for Total Engineered Filtration Solutions. We offer end-to-end solutions from Filter Media to Industry-Leading Filtration Equipment, to Spare Parts & Accessories, to On-Site Field Services and In-House Laboratory Services. Whether for your Filter Press, Belt Press, Leaf Filter, Vacuum Filter, or Baghouse, you can count on Micronics’ deep industry and applications knowledge for the right engineered filtration solution to meet your needs. We look forward to working with your team.