This month we are zooming in on a recent filter media upgrade in the Reverse-Air Baghouse in a Coal-fired power facility in the western USA.

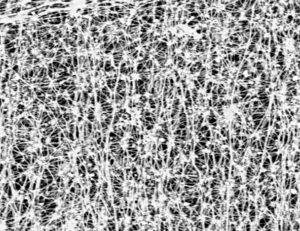

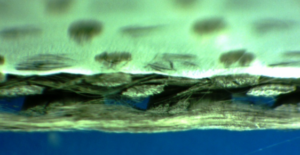

This filter media upgrade to a woven fiberglass fabric with ePTFE membrane laminate delivered many quantifiable benefits to the Station and supported their commitment to full compliance with all environmental regulations, reduced opacity incidents, and a 62% increase in power production.

With Micronics’ partnership, the client’s Reverse-Air Baghouse is now a productive and reliable asset for the Power Station.

Read the full Case Study below and let us know how the Micronics Engineered Filtration Group can assist with your baghouse challenges. With our problem-solving, technical expertise, innovative filter media solutions, and field service capabilities, we are committed to your success.